Wiring, mechanics and design are three things one might assume a student would learn through participation on a high school robotics team, but Brian Jones said his students on the Harding Academy team have learned a lot more than how to build a robot.

“They dedicate their time to this,” said Jones, who is both the team’s coach and a math and science teacher. “And it’s more than meets the eye. We’ve got a public-relations side, communications skills, and they have to know how to cooperate with people they’ve just met at competitions.”

The Harding Academy robotics team has won at two regional competitions this year — the Arkansas Regional at Harding University in Searcy in early March, and the Bayou Regional in Kenner, La., in early April — and will compete in the FIRST Championship event in St. Louis, Mo., on Wednesday through April 26.

The FIRST (For Inspiration and Recognition of Science and Technology) mission is to “inspire young people to be science and technology leaders,” according to the organization’s website.

This year, the FIRST Robotics Competition revolved around a game called Aerial Assist. Teams from around the country have built robots intended to move large exercise balls that are 2 feet in diameter through goals that are 6 feet, 10.75 inches off the ground. There are also low goals that are only 7 inches off the ground, but they do not yield as many points.

When the teams arrive with their robots, they are set up into alliances with two other teams. The game is played between two alliances made of three robots each. As teams gain points and move to the next round, they are able to choose their own alliances.

“The more robots on the team that touch the ball, the more points you get when you score,” said Harding Academy senior Ronnie Clements, who has been on the school’s robotics team for three years.

Clements’ role on the team this year was in public relations. He helped with the robot, but his focus was on making awards for the team, creating a video for the judges depicting how team members worked together and showing a business plan for all of their work.

“It’s not just about the robots,” he said. “It’s also about community.”

Next year, Clements plans to attend Harding University as a freshman. He said he intends to study biomedical engineering, and his time on the team has helped him in several ways.

“I wouldn’t have any idea how to use any of these machines,” he said. “It’s also really put an edge on my social skills, having to do PR and make alliances.”

Freshman Alina Westbrook said that when members of the Harding team learned about Aerial Assist, they knew they had to design a robot that would be able to move the ball into the top goal. The two main suggestions to achieve this were a catapult and a claw, but the team ultimately went with the claw design.

“We found the simplest subsystem, which is the claw, so we went with that,” Westbrook said. “It was absolutely amazing to see something I helped make actually work.”

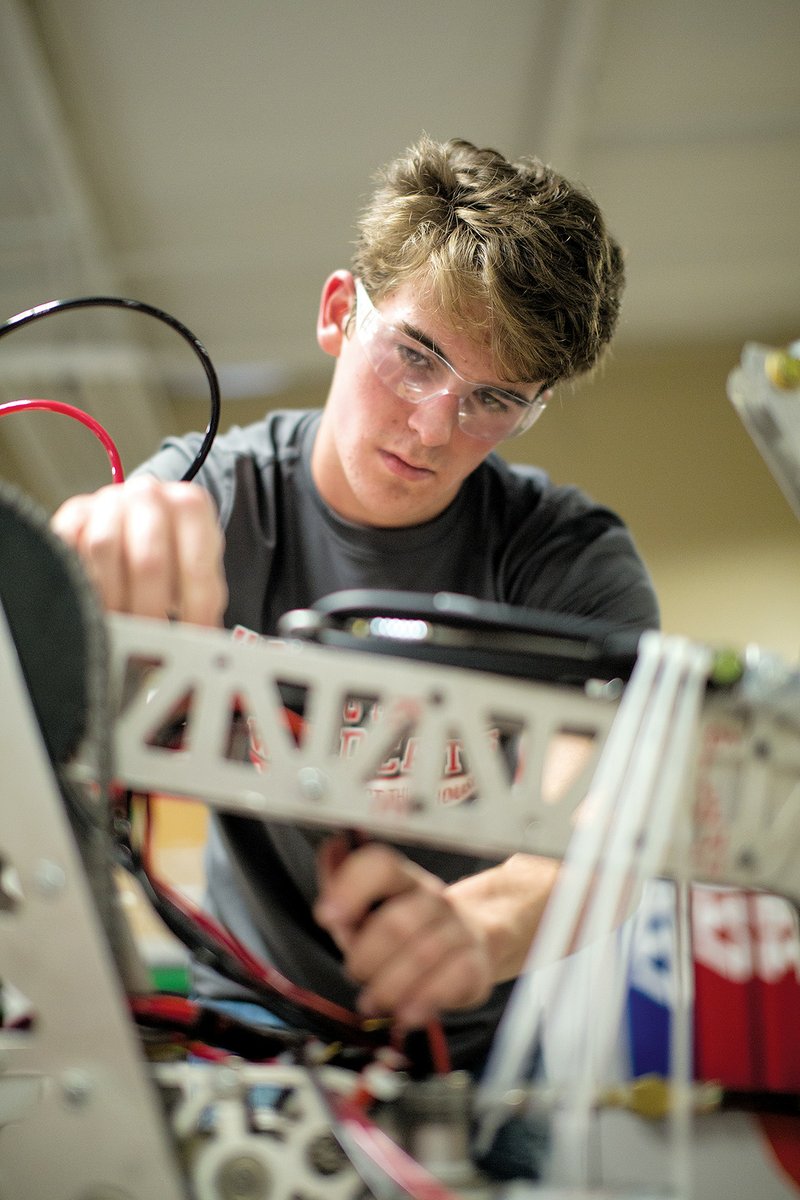

Westbrook worked on wiring the robot, which she said was a new experience for her when she joined the team.

“I thought that wiring and electrical work was really sophisticated,” she said. “Now it just makes sense to me.”

At competitions, Westbrook said, she takes mental notes about other robots and looks at the pros and cons of their designs, but the robots are not the only thing she gets excited about.

“Even though building the robot is a lot of fun, being around all of these people is the really cool part,” she said.

Senior Greyson Spears was on the design team this year, and he said the claw was the simpler of the two designs in the long run.

Last year, Spears was more involved in the building part of the process. Through that experience, he worked with CAD — computer-aided design — and this year he stepped into the design role with that experience.

With CAD, Spears was able to virtually build and test the claw design on the computer before using any material. The CAD program helped show exactly how the claw would work and what pieces team members would need to build the robot. The program also printed off plans and showed how to cut the metal to make sure everything lined up.

“Without it, you’ll cut out a billion different things and waste a ton of time,” Spears said.

Like Clements, Spears plans to attend Harding University in the fall and pursue a degree in biomedical engineering. His father is an anesthesiologist, and Spears said biomedical engineering pairs the skills he has learned on the robotics team with his desire to do something in the medical field.

“I can help people while using engineering,” he said. “I wouldn’t have any idea what I’d be majoring in if it wasn’t for [the robotics] program. And after a year, if I decide that’s not what I want to do, I can still change my major.”

The Harding Academy robotics team is still a young program. Jones has been coaching the team since he started working at Harding Academy three years ago, and he said the team keeps improving now that it has a mix of newcomers and experienced team members.

Staff writer Angela Spencer can be reached at (501) 244-4307 or aspencer@arkansasonline.com.