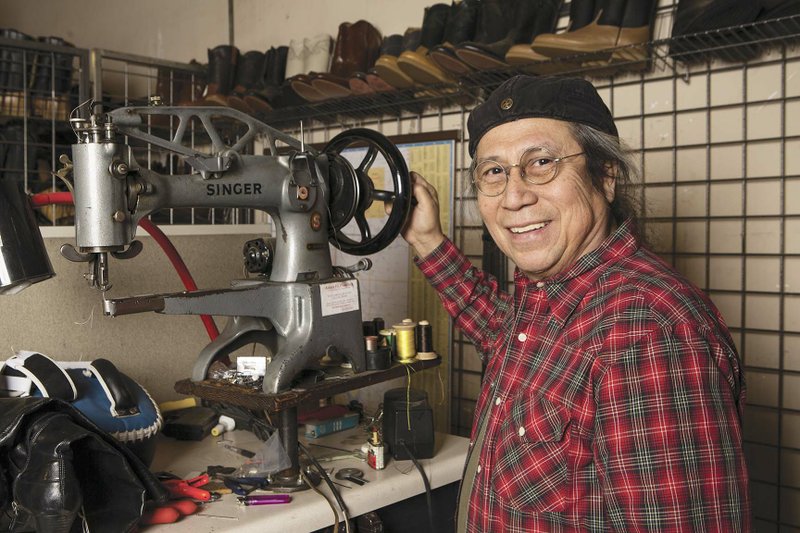

James Cedillo, wearing a beret, and round, wire-rimmed glasses, his hair in a ponytail, emerged from the back of B&H Shoe Repair Shop in downtown Conway and waited on customers as classic rock played from a satellite radio on the counter.

“Let it flow — let good music fill the atmosphere for my customers,” said Cedillo, 62, spreading his arms and smiling.

Ah, his customers. “I have all kinds of customers,” he said, laughing, as 65-year-old Vietnam War veteran Jim Park of Vilonia came in, sat on a bench inside the store and started talking about everything from pole dancing to Pavlov’s experiment with dogs.

Park was holding leather saddlebags that needed to be repaired.

“I’m not taking them to the county fair,” Park told Cedillo. “Glue it; sew it; put some magic dust on it.”

The door opened every few minutes, bringing in another customer — young, middle-aged and older. Cedillo said his customers include people from all walks of life — bankers, a retired state senator, students, mothers, young professionals.

A young woman came in and picked up a leather strap for her purse that Cedillo had repaired.

“Is that what you wanted?” he asked. “It’s perfect,” she said, smiling back at him with her response.

Another woman brought in a pair of her son’s Sperry Top-Siders, one of which had a frayed shoestring, thanks to their dog. The shoestring was woven into the interior of the shoe, so she couldn’t replace it. “I have something similar,” Cedillo told her, looking at the string. “Do you know how much it’ll be?” she asked. “Let’s see,” Cedillo said, hesitating only a second before telling her $6.

A man came in with a pair of brown leather shoes that had the wrong color of polish used on them and just needed the shoes polished and shined. Cedillo suggested he leave them overnight.

“I’ll clean all this stitching and make them look new,” Cedillo said, running his finger around the shoe where the leather was stitched to the sole.

Henry Mitchell isn’t a customer, but he’s a regular at the store. Sometimes he spends his days on the bench out front on the sidewalk, drawing. This rainy day he was inside the store sketching, bidding customers a good day as they left.

An old-fashioned school bell sits on the counter for customers to ring if Cedillo’s in the back — he’s a one-man show.

Cedillo took over the shop 20 years ago in 1994 from Bill and Hazel Rhea, thus the name, B&H. Cedillo, who grew up in Mexico, started at age 14 as a shoeshine boy for Bill Rhea in McAllen, Texas. Rhea started working at International Shoe Co. in Conway and later sold boots and shoes at stores in various locations, including Conway and McAllen, Cedillo said.

Cedillo started working with the machines and became manager of the shop in Texas, but when Rhea closed his stores in Texas, he kept the one in Conway. Cedillo said Rhea called him when he was thinking about retiring and asked if he wanted to lease or buy the business.

“I tried it for about a month. I said, ‘You know what? I’ll buy the place,’” Cedillo said. He said he worked from 7 a.m. to 7 p.m. every day to get it established. “I needed the money to pay the note, expenses and stuff. And back then, we didn’t have that many customers.”

He said he finally paid off the business this year.

“Shoe repair is not a profitable business. That’s why a lot of shoe-repair shops closed,” Cedillo said. Twenty years ago, B&H was one of four in Conway, he said. The closure of shoe-repair shops could be attributed to our throw-away society, but Cedillo thinks it’s more about how hard it is to earn a living doing it.

“I don’t mind working long hours and charging a reasonable price,” he said. “In other words, I look at the cost of the shoe, so I can adapt to what people can afford to pay to repair a pair of shoes. I give them choices.”

Cedillo sells new and used boots, which line racks around the wall. He repairs all kinds of items, but he said his specialties are cowboy boots and men’s dress shoes. He showed a pair of boots whose soles were coming off. If it’s a $500 pair of boots, and it costs $60 to fix them for years’ more wear, it’s worth it, Cedillo said.

People have two options, he said: to throw away a pair of shoes and spend $45, for example, to buy new ones, or spend $6 to get the new laces on a dog-chewed Top-Sider.

“The way I see my job, I look at shoes that have been fixed by somebody else. I look at them and see what kind of work they did, and I try to make it better,” he said. “That’s how I’ve been surviving — I’ve been trying to make it better every day.”

He does most of the work on a faithful 1965 Singer sewing machine, and underneath a skyscraper of cardboard boxes in an area in the front of the building, he has surplus machines he bought when a shoe-repair business in Little Rock closed.

“I fix all the Conway Fire Department’s turnouts,” he said, holding one up. Cedillo, for years, has been the go-to guy to repair orthopedic shoes for the Conway Human Development Center’s clients, which he said is rewarding.

Conway is growing, he said, and that’s a lot of shoes to repair.

“Every year I get more customers, and more customers and more customers,” Cedillo said.

He was nonplussed to hear that another shoe-repair shop had opened.

“I’m not surprised because I’m used to it. There were three more that couldn’t handle it. I don’t think it’s going to affect me at all. I’m confident,” he said. “I could invest in a nice place, modern — but I don’t think it’s needed. I think what matters the most is, fix the shoes.”

Just under a half a mile away, at 405 Oak St., Cobblestone Quality Shoe Repair opened in October in a strip center.

Ty Lanehart, 46, said he got into the business about eight or nine years ago because of his interest in Civil War re-enactments. He apprenticed with Richard Barber of Little Rock, the Conway shop’s co-owner, who has owned Cobblestone Quality Shoe Repair in Little Rock for almost 25 years, Lanehart said.

“My roots kind of go back to childhood,” Lanehart said. “I do and did a lot of re-enactment. A lot of their gear back then was leather — shoes, bags, belts, cartridge boxes.” He started participating in Civil War re-enactments at age 13 or 14, he said, and is a member of the 1st Arkansas U.S. Volunteer Cavalry. Lanehart rides horses using period saddles — ones he often repairs.

Lanehart said he went into Barber’s shoe-repair shop in Little Rock looking for a heavy cotton thread to use to tie boots for a re-enactment, and Barber invited Lanehart to stay and look around.

He had a lawn-care service in Little Rock and became Barber’s apprentice on weekends and rainy days, honing his skills.

In Lanehart’s shop, cardboard shoe boxes are organized behind the counter for “singles,” Lanehart said. New chairs, a light-colored rug and framed art coexist with antiques, including a wooden stitching pony Lanehart bought at an antique store.

Racks in another room hold larger boots, and hooks hold purses. Colored threads are organized in a case on the wall, and hardware and accessories are organized together — buckles, grommets, heels. He uses two sewing machines, including one blue Singer machine he said is probably 100 years old.

He hesitates to call himself a cobbler. “I’d say a cobbler, but for me, there are so many parts to it. We sole shoes, fix heels, do zippers, fix snaps. When do you become a cobbler — when you learn 1,000 things, or just 800?” The possibilities are almost endless, he said. “Everybody who comes in here has a different problem,” he said.

Lanehart also performs custom work. “It’s a real pleasure to work on real leather,” he said.

“I had a survivalist come in and ask me to make a scabbard for his homemade machete,” Lanehart said. “I made him like a bug-out scabbard. It had pouches and places to attach little doohickeys. He was thrilled.” People sometimes have an idea in their minds of what they want on custom pieces, and Lanehart said he tries to exceed their expectations. “He practically danced out of here — he loved it.”

Lanehart loves a challenge, too.

“A lot of times I say, just challenge me,” he said. “I’m always trying to learn different things and new techniques.” Lanehart gets a kick out of asking his customers to try to identify where he fixed an item because he tries to make the repairs seamless.

If a bag or boot is a lost cause, sometimes he will create a new design to patch it — a leather heart, for example — to make the item wearable. Sometimes the item is better than new when it leaves his shop, he said.

People get attached to their belongings, he has learned.

“Maybe it’s their favorite purse, or something that belonged to their grandmother. They’ll say, ‘Can you fix it?’ They’ll set it down, and pick it up again and just cradle it,” he said.

Repeat customer Darla Cathcart of Conway brought in three pairs of boots for Lanehart to coat with protectorant for the winter.

She said her first experience with Lanehart was because a heel of a new pair of shoes got caught in a grate as she and a friend were going into a restaurant. The waiter came to help, and she cautioned him to be careful not to hurt her beautiful shoe.

“My friend said, ‘You should take that shoe to your cobbler.’ I was like, ‘I don’t have a cobbler. Do cobblers even exist?’” Soon afterward, she said, she heard about Lanehart’s shop.

“They expect a little 80-year-old man to come out with an apron on,” Lanehart said, wearing bluejeans, tennis shoes and a baseball cap with the store’s name on it.

Lanehart said that a couple of years ago, it seemed like more of a throwaway society, but the “green” movement is prompting more people to get items repaired rather than get rid of them.

“Nothing goes to waste at a shoe store,” he said. “A pair of shoes you can’t fix may have a buckle you can use, or you cut tops out of boots to repair another. We cut up a purse in Little Rock and probably used it to make 100 things.”

Lanehart showed a designer Michael Kors purse ready to be picked up. He’d fabricated a pin for the handle, which was coming off. The most expensive purse he’s worked on cost about $3,500, he said. It had the price tag on it. Sometimes, he said, people pick up a flawed purse on sale and bring it to him to fix for a few dollars. A woman recently brought in a pair of $900 shoes she’d damaged running after her dog.

On the other hand — or foot, Lanehart said he will have a customer bring in an old pair of favorite yard shoes to be repaired.

Lanehart said college students have called, hesitantly asking about his services, because their parents or grandparents had shoes repaired, but not them.

“People will say, ‘I’ve never come to a shoe shop — do I need to make an appointment? Is it real expensive?’” Lanehart tells them no and no.

Like Cedillo, Lanehart said his customers are from all walks of life and ethnicities. “It’s such a rainbow of people,” he said.

Cedillo and Lanehart both said they have been called artists, and they accept that moniker.

“Yeah, it’s an art to do this kind of work,” Cedillo said. “If you don’t take it that way, you’re just one of the rest.”

Shoe repair may be a dying art, but it’s a satisfying one, the men said.

“Most people are real appreciative,” Lanehart said. “The gratification you get and the appreciation you get — I really feel like I’m helping people.”

Lanehart looked down at his hands, fingers stained from shoe polish.

“Cobbler’s hands,” he said, smiling.

Senior writer Tammy Keith can be reached at (501) 327-0370 or tkeith@arkansasonline.com.