Community leaders in Little Rock are collaborating to produce thousands of face shields for front-line hospital workers battling the coronavirus outbreak in Central Arkansas.

Health care workers are facing a shortage of masks and face shields to protect them as they treat infected patients and try to control the spread of covid-19.

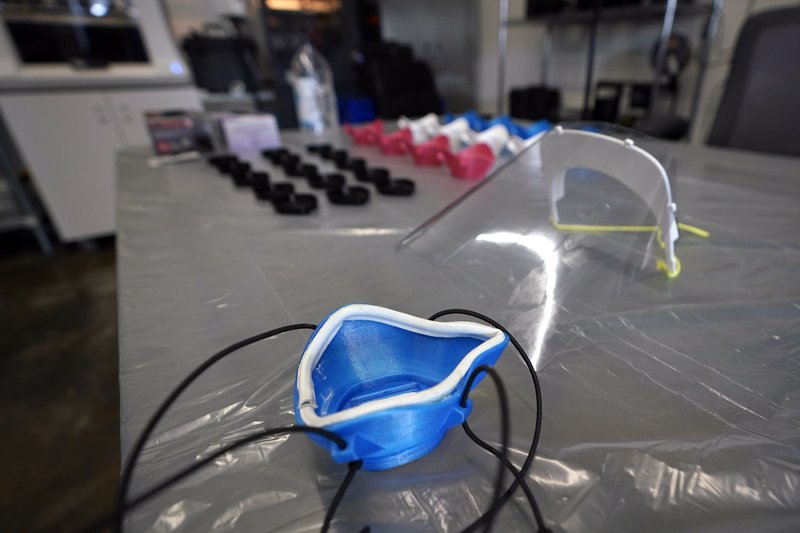

So far, the University of Arkansas at Little Rock has produced about 250 face shields for workers at CHI St. Vincent hospital and clinics in Little Rock. The university has built a "3D print farm" on campus to manufacture the face shields, said Larry Whitman, dean of the Donaghey College of Engineering and Information Technology at UALR.

"Everyone wants to do what they can to provide the protection our health care workers need to respond to this crisis," Whitman said.

[CORONAVIRUS: Click here for our complete coverage » arkansasonline.com/coronavirus]

The Little Rock School District also contributed 3D printers to help with production. "We jokingly call it a rapid production process," Whitman said, noting that the effort churns out about eight to 10 face shields per hour under ideal conditions.

That's about to change thanks to the partnership pulled together with help from industries and the Little Rock Regional Chamber of Commerce.

Lexicon Inc. will use its machinery to make aluminum headbands to hold the masks in place, replacing a plastic product that takes longer to assemble. Mr. Plastics of Little Rock is also helping with production and Sage V Foods has contributed funding to the effort.

"It's really been a team effort all around," said Jay Chesshir, president and chief executive officer of the Little Rock chamber.

Expanding beyond the 3D printing effort, Chesshir said manufacturing soon will ramp up and enable production of enough face shields to support the six major hospitals in Central Arkansas. The team hopes to have enough material to also supply first responders.

"We believe we're going to be able to make 1,000 to 2,000 per week," Chesshir said. "We're ramping up to get ready for the surge in the virus locally. It's important to prepare and make sure we have the gear the hospitals need."

Whitman was delivering 100 masks fresh off the production line to St. Vincent on Wednesday afternoon.

"The great thing about face shields is they offer more protection than masks," he said. "What we're producing enhances protection -- this doesn't replace a mask. It's used in addition to the mask."

Finding enough plastic to support production was difficult, and ACI Plastics Inc. volunteered to help.

Like the difficulty finding cleaning products in the grocery, it's challenging to find large supplies of plastic since other communities also are conducting similar efforts. ACI was able to locate 542 sheets of plastic in Houston on Tuesday. "I literally had about five minutes to decide whether to buy it, the need out there is so great," Chesshir said.

One sheet of plastic can produce about eight face shields, so the supply should be enough to meet anticipated needs, Chesshir said.

"The great thing about the face shield is that each one can be cleaned between shifts and reused," he added. "When the surge comes, we think we'll be ready."

Business on 04/09/2020