As we plunge into winter, you have time on your hands if you don't hunt waterfowl or bowhunt for deer.

Unless you're a bass tournament fisherman, you probably don't fish in the cold, either, which leaves not much else to do except rage at broadcast news and strain all of your relationships.

Thankfully, there is an alternative. If you hunt or shoot recreationally, you've noticed how hard it is to find ammunition. Sidestep shortages and start loading your own.

For most hunters, factory centerfire metallic ammo is fine for all deer hunting in Arkansas, but if you want to wring the best performance from your rifle or handgun, custom reloads are the ticket. You can tailor one or more loads to your particular firearm. You can make them go as fast as your rifle's action will allow, and you can get the tight groups that make you comfortable shooting long distances.

Since you are no longer confined to ordinary Remington Core-Lokts, Winchester Power Points or Hornady Interlocks, you can experiment with custom bullets. We say this as the great fans that we are of Remington Core-Lokt and the Hornady Interlock bullets. My favorite bullet is the Speer soft point, flat base and boattail. All of those are primitive by modern standards, but they are very accurate in several of my rifles with multiple reloading recipes.

If you want better ballistic coefficients for flatter, straighter trajectories over long distances, you can reload with Berger bullets or Hornady ELD.

Beginners can get everything they need to load high-quality ammo in kits made by RCBS, Hornady, Lee and Lyman. A kit comes with a press, balance beam scale, powder dispenser, chamfering/deburring tool, primer pocket cleaning tool, case trimmer, case lubricant loading block, priming tool, primer tray, powder funnel and reloading manual.

Reloading dies, bullets and primers are not included.

I still use the same RCBS Rock Chucker kit that I bought in 1996. I use Lee Precision dies, and I use a digital scale along with the balance beam scale to measure every powder charge. I am a stickler for precision charges, and I refuse to risk a squib load or an overload to a dispenser.

The extra time it takes to double-weigh charges is not inconvenient because I do not load large quantities of ammo at a time. A big lot for me is 40 rounds, only 10 of which have the same powder charge. For that reason, I am just as likely to use a Lee Loader, a simple little tool that allows you to load ammo anywhere, including picnic tables at roadside rest areas. Yes, I have done it many times. Reloading snobs that are devoted to Redding and other expensive brands make fun of my Lee Loaders, but in standard hunting rifles, I'll put my Lee Loader ammo up against anybody's.

A lesson I learned early is to test your ammo before loading a quantity. My first load was for 308 Winchester using 165-grain Nosler Ballistic Tip bullets with a charge of BL-C2 powder. The Nosler Reloading Manual listed claimed that the most accurate load tested. I loaded 100 of them. Guess what? It took only three to determine that it wasn't accurate in my rifle.

This led me to my next purchase, a bullet puller. It's a hammer with a screw top and a collet. You insert a loaded cartridge into the collet, screw down the top and bang the thing on the floor until inertia knocks the bullet out of the brass and the powder drains out into the hammer head. It takes a very long time to pull 97 bullets. It's a mistake you'll make only once.

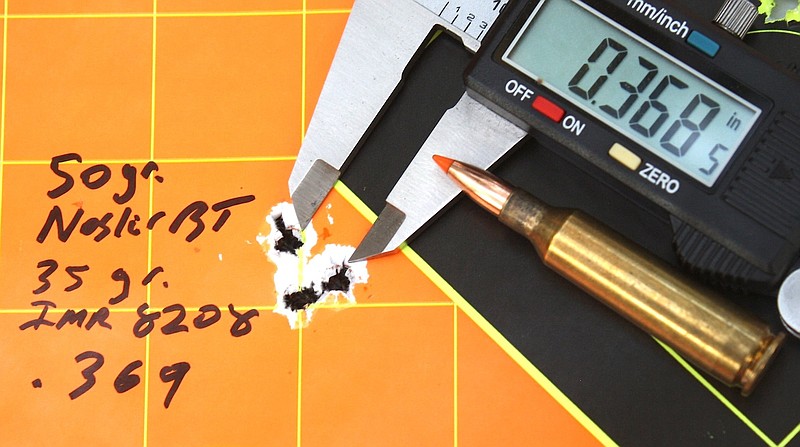

For testing, I load only five cartridges. If they group well, then I try to tighten them by increasing or decreasing the powder charge and using different primers.

You can use new brass or spent brass from factory ammo that you bought. Every die set comes with a full-length resizing die that restores a brass cartridge to factory dimensions. A neck-sizing die sizes a cartridge to the dimensions of your rifle's chamber.

Lubricate brass before sizing. A dry cartridge will stick inside a die. To remove it, you have to remove the decapping pin from the die and punch out the brass with a metal punch. It is difficult, and you risk damaging your die.

Use a very small amount of lubricant. Too much will dent your brass. I lube just one cartridge and then resize the next two or three with residual lubricant in the die. When I encounter resistance, I back a cartridge out and roll it across a lube pad before continuing. That little bit of lube will be enough to lube two or three more cases.

With the chamfering/deburring tool, condition your case mouth and use the primer pocket cleaning tool to grind primer residue from the primer pocket.

The next step is to prime your brass. The primer tool that comes in a kit attaches to the press. It primes one case at a time by lowering the ram onto the tool.

It's a lot faster and easier to use a separate priming tool. It's a hand-held device that enables you to prime a lot of cases quickly, and it is worth every penny.

Next, measure a charge of your desired powder and drop it into the case with the powder funnel. Again, I charge only five cases at a time and label them. I leave uncharged cases upside down in the loading block so I don't lose track of which cases I've charged.

After charging your cases, you are ready to load your bullets. Remove the resizing die from your press and install a bullet seating die. Reloaders argue endlessly about the proper depth for seating bullets. Except for the 6.5mm Creedmoor, whose chamber and throat dimensions are uniform among all manufacturers, seating depth is highly variable. You can buy or make tools to determine proper seating depth, or you can experiment. There is a lot of information and a lot of opinions about this subject on a myriad shooting websites. Absorb what you can from these sources and develop a method that works for you.

Before reloading the next batch, measure your empty cases. If they have stretched over spec, trim a tiny amount of metal off the case mouth to get it back within spec. Check spent cases for damage, such as splits in the necks or stretching around the base. Discard damaged cases.

That is all there is to it. You now have ammo that is ready to shoot. Few things in shooting are as satisfying as shooting tiny groups or taking game with ammo you loaded yourself.